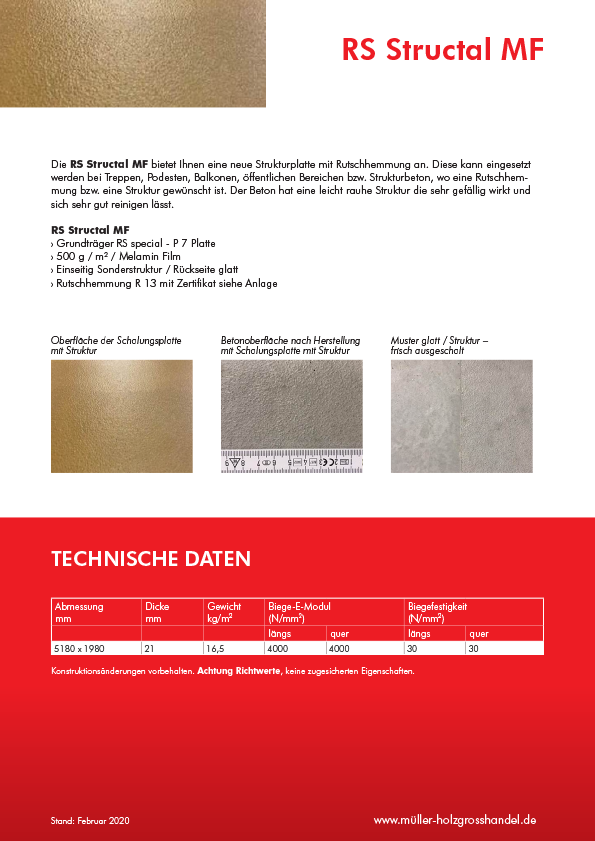

Produktvorstellung RS Structal MF

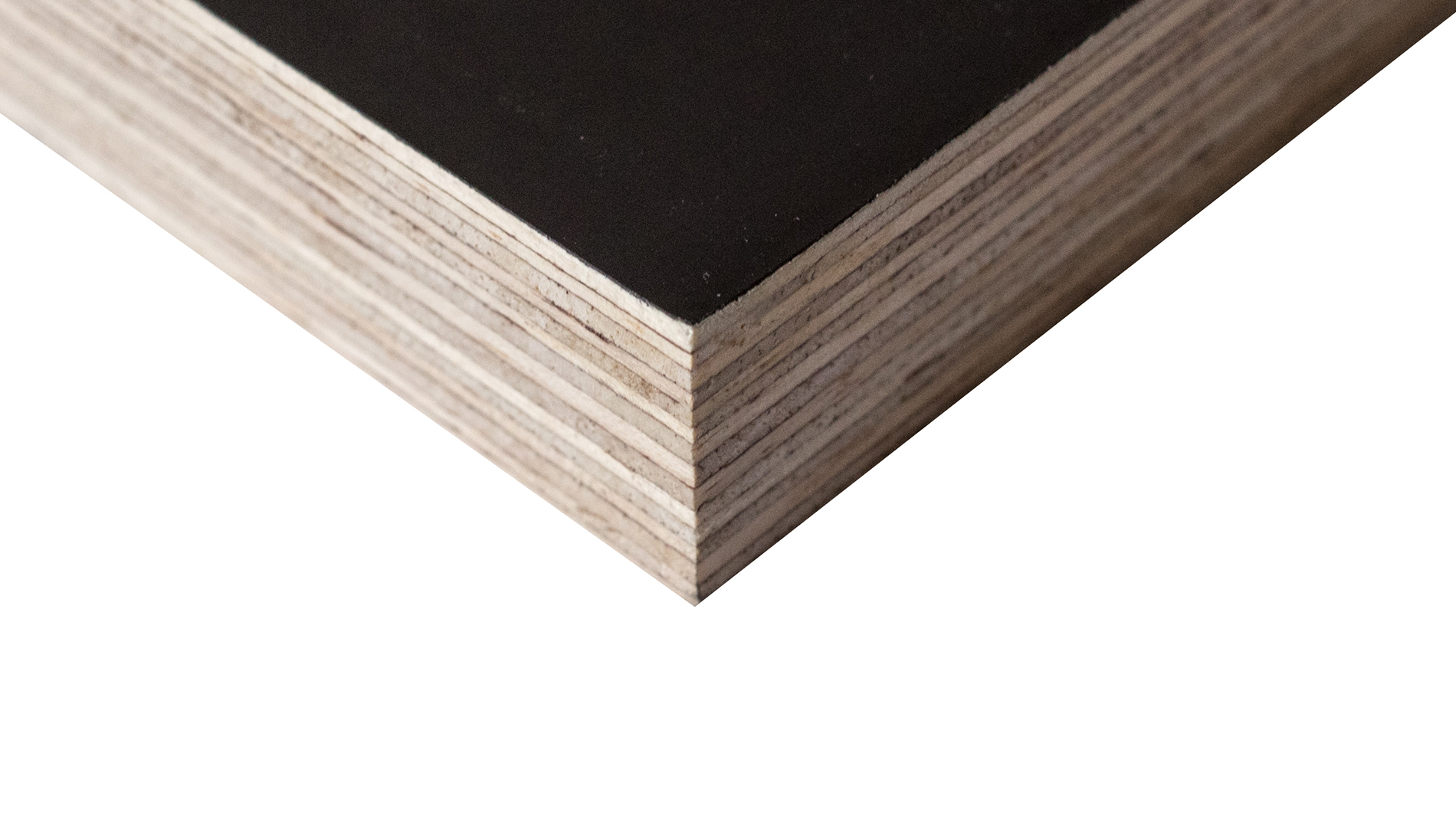

Die RS Structal MF bietet Ihnen eine neue Strukturplatte mit Rutschhemmung an. Diese kann eingesetzt werden bei Treppen, Podesten, Balkonen, öffentlichen Bereichen bzw. Strukturbeton, wo eine Rutschhem- mung bzw. eine Struktur gewünscht ist. Der Beton hat eine leicht rauhe Struktur die sehr gefällig wirkt und sich sehr gut reinigen lässt.RS Structal MF› Grundträger RS special [...]